SMI Increases Points of Distribution & Speed to Market for L’Oréal

L’Oreal Needed to Improve the Process for Product Resets Spanning:

L’Oréal launches new products every 6 months to meet the changing needs of customers. New items are added, slower selling SKUs are phased out, Planograms (POGs) are developed and new fixtures, graphics and merchandise are shipped. All of these steps must take place before reset can take place in stores. L’Oreal needs impeccable execution and speed to market to get the most out of their reset efforts, but the company faces significant challenges.

The Problem

– Supply chain blind spots

– Timeline uncertainty

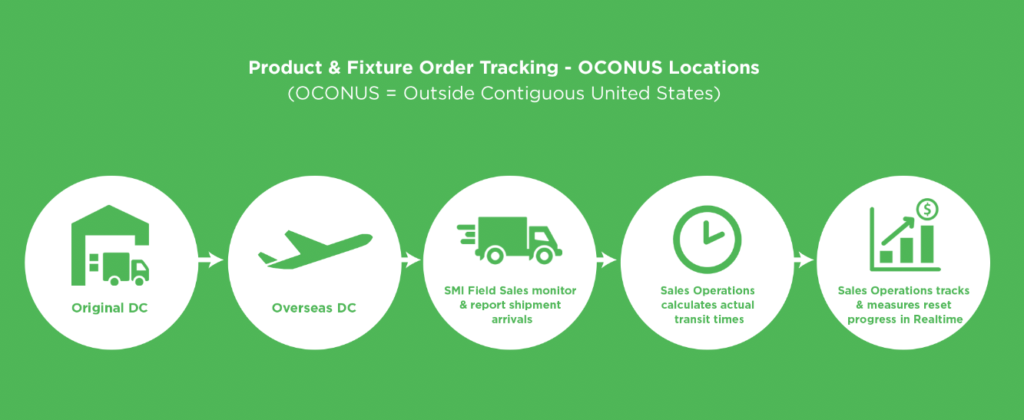

– International shipping regulations and customs

– Assigning the appropriate reset POGs to thousands of locations

– Gathering appropriate feedback from the field

– Confirming reset execution through photos

The Solution

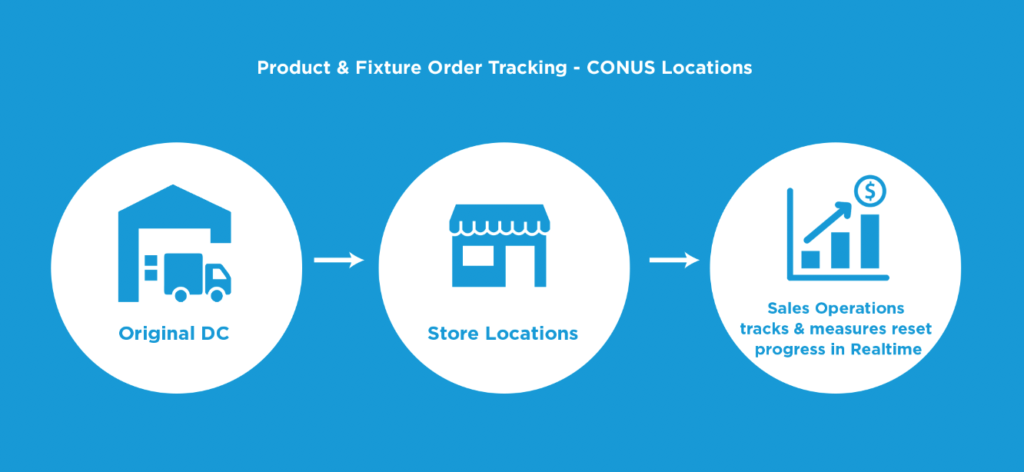

– Pin point and track the supply chain to calculate in-store arrival dates on a global scale.

– Create, align, schedule and deploy assignments to designated staff at specific locations.

– Collect data and verify work is being performed according to the standards that are set by the client.

– Share reporting results across the operation.

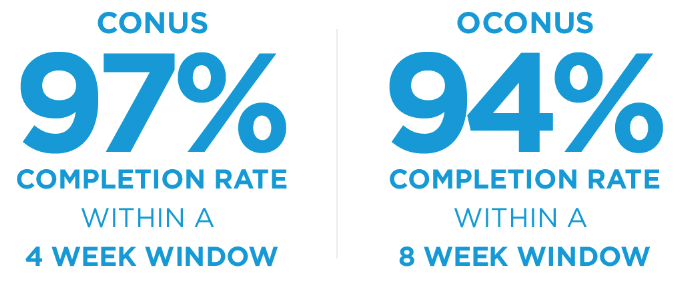

The Results

At the end of the reset initiative, SMI provided project level reviews, real-time reporting and recaps to L’Oreal and collected data required to enable future improvements. SMI secured imagery and feedback from on-site staff members and mapped labor management by planned versus actual for further study.

If your retail team is considering partnering with retail supply chain and management experts, click here to start a conversation about your needs.